Why we recommend this Drilling and Tapping ARM: The stand-out feature of this Arm is that it’s going to save you hours of time helping you to accurately and quickly drill and tap work pieces and its always setup ready to go.

This is an electric tapping arm and it is one of my favorite tools in my shop. It’s probably one of the fastest returns on investment that I’ve ever made on a new machine tool. Being a small home machine shop one of my frequent jobs is to drill and tap metal parts. I make a lot of machined parts and one of the things that those parts usually need is a drilled and tapped hole. So I have a bunch of equipment in my machine shop just for that, including tapmatic tapping heads, a tapping station and numerous hand taps and dies. If you’ve ever tapped threads in metal, you know that it can be a harrowing experience. When you don’t have the right stuff it can be an experience of misaligned holes and broken taps ruining a part, and it can be really frustrating.

Flexible Tapping Arm Machines

You may have seen other tapping arms like this and there are a number of different brands out there. I found out about this electric tapping arm machine from a friend and I thought this would be a really amazing labour saving tool for my shop, and it turns out I was right.

When I purchased mine the asking price was about twelve hundred dollars US plus the cost of a few accessories that I got along with it. I made that money back within the first couple of months of having it just from time and work flow savings and quality improvements in my products. At this point, it’s helped me raise my standard with all my drilling and tapping jobs that I previously did, either by hand or with the drill press.

About the Tool

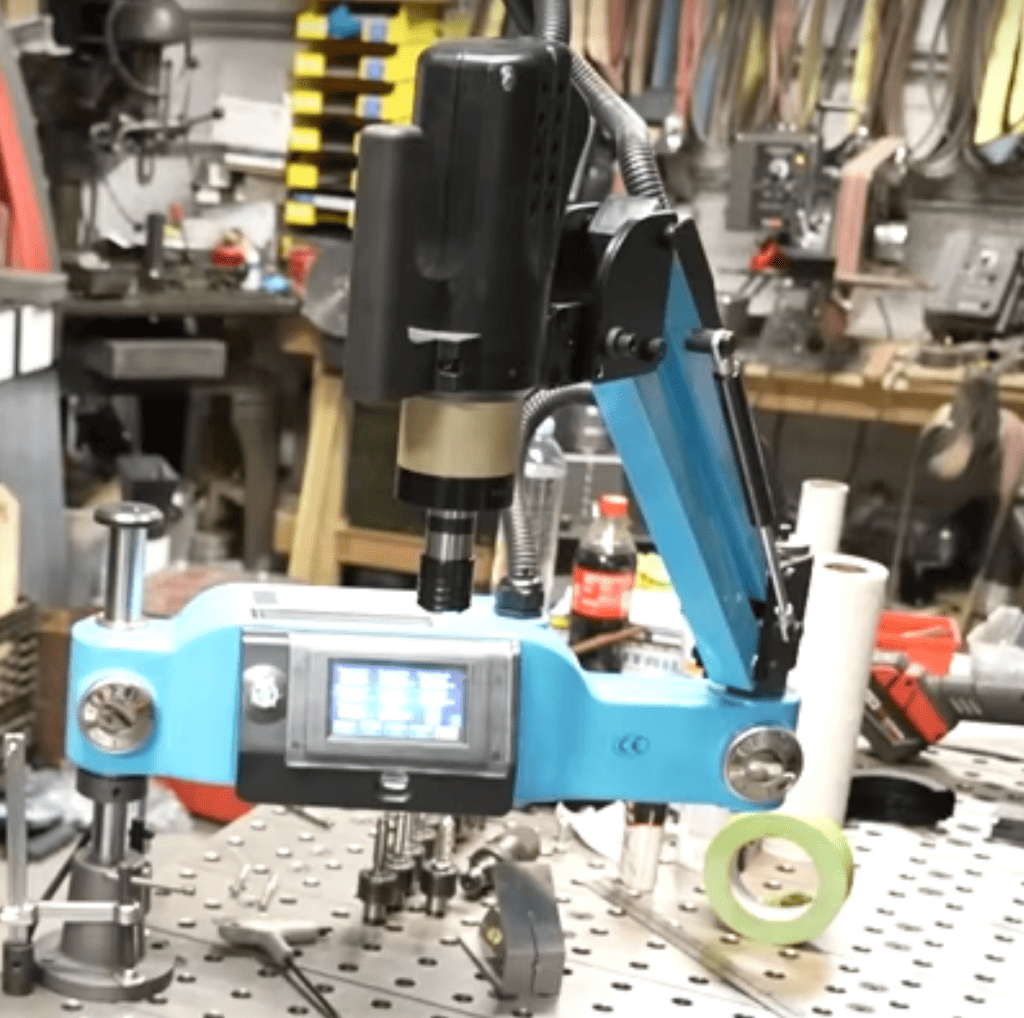

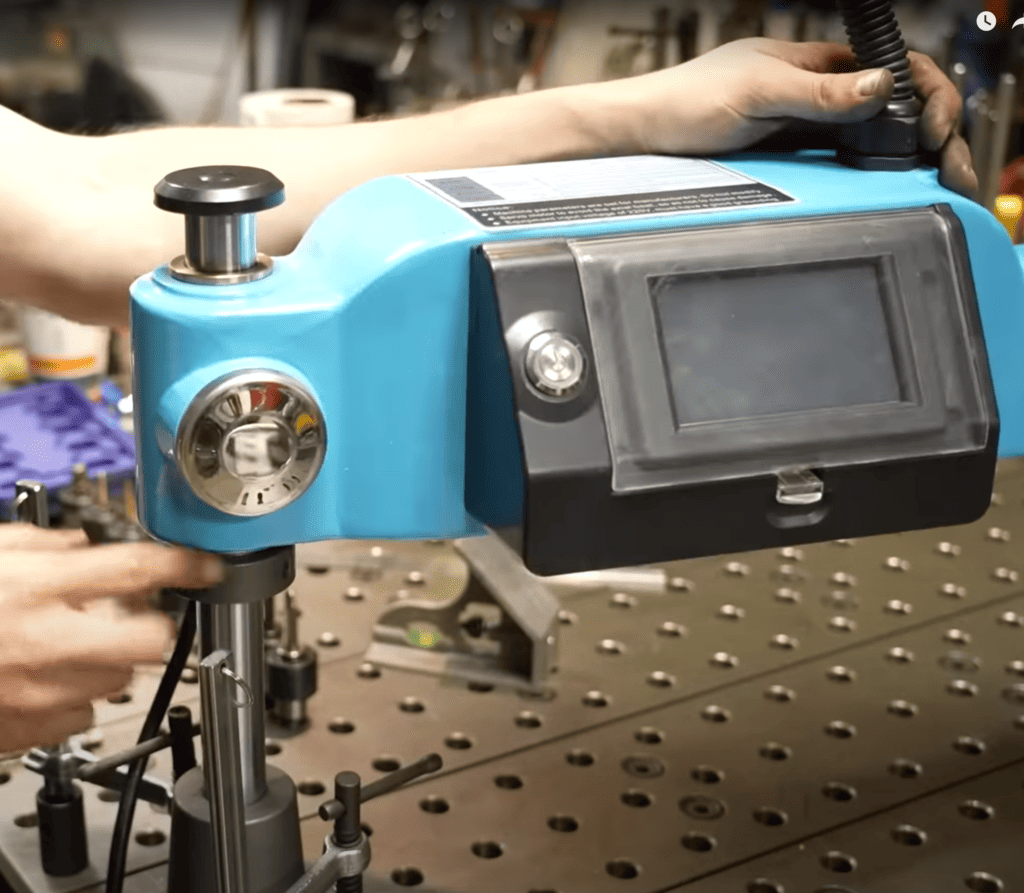

I want to tell you about some of the features and show you how it works and why I think you might want one of these in your shop. The actual motor in the arm is a digitally controlled servo motor system with a control system that allows precise user control. The Arm sits on a main cylinder to which the blue articulated tapping arm attaches that includes a gas strut so you can smoothly move it around the table and up and down. The Arm stays perpendicular to the table or parallel basically due to the column so no matter where you move around your work table. I can actually just drill and tap anywhere on the table without having to move whatever the part is that I’m working on.

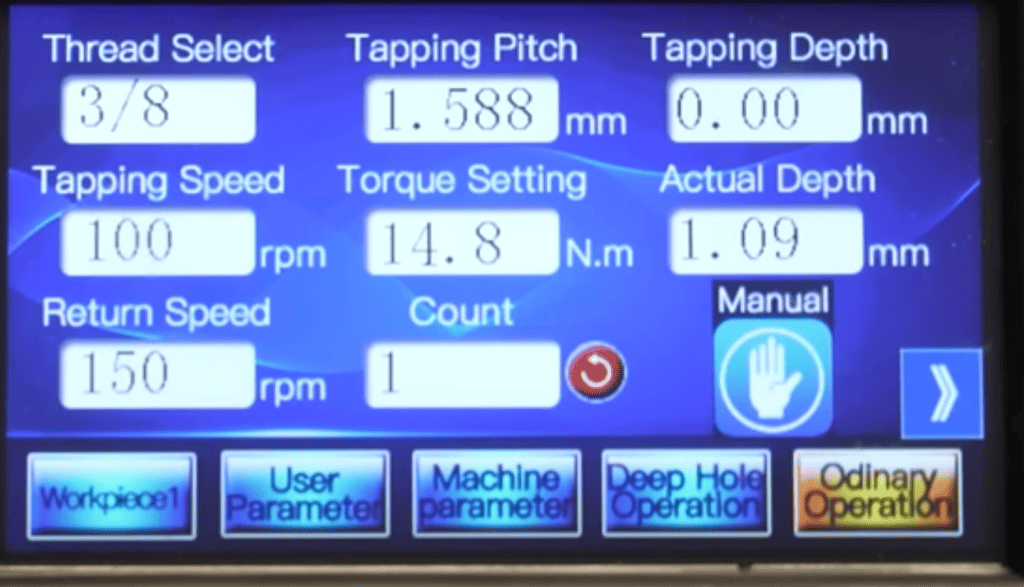

You use the Tapping Head by pressing the buttons on the handle, the lower one rotates the spindle clockwise and the button above reverses the drilling/ tapping rotation. All the settings are adjusted on the screen, on the main arm, giving you a bunch of speed and depth options. There’s actually a smart torque setting that will actually stop the machine if it feels a certain amount of torque and automatically reverse the drill or tap out of the work piece. The machine is designed in metric and you set the tapping pitch and it automatically sets the torque setting based on the tap size.

As a Chinese machine I was worried if it was going to be in metric only but it does have an English display and does include settings for standard inch threads. The settings do show some large TAPS but this machine really shouldn’t go much larger than a half inch tap. Having tapped with a three-quarter inch tap I found the machine to struggle and that thread was a little bit rough.

Setting for Imperial Threads.

Automatic and Manual Settings Options

The Arm has both manual and automatic settings. Automatic mode basically controls all your tapping depths and settings. In manual mode I get the option to set the tapping options and set the depth that the machine drill / tap to. In the picture I have set the tapping depth to 10mm when I push the tapping button, it will rotate to a depth of 10 millimetres stop and it will reverse out at the ‘return speed’ setting, which is pretty cool – shown in the picture below. So if you’re tapping a lot of holes you can set the ‘Tapping Speed’ and the ‘Return Speed’ and the Arm will follow those settings. As we see below, if I was going to tap, let’s say half inch I would set my tapping speed to probably at 100 rpm and the reverse speed at 150 rpm.

Tapping Arm Control

This automatic tapping setup approach saves a lot of time and stops you relying on tapping by feel which is slow and likely to cause broken taps. There is also a ‘Deep Hole’ operation which is amazing, the arm will do a rotation cycle-down and then back-out a little bit and then cycle-down and back-out a little bit and cycle-down basically breaking the chip as it goes.

Horizontal Drilling and Tapping

The Tapping Head can be rotated to Drill and Tap at 90 degrees allowing you to work on parts and assemblies from different orientations. So let’s say you were working on a large frame that needs drilling and tapping from the side, you can simply re-orientate the head by loosening a couple of Allen key screws and you can actually turn the head 90 degrees, retighten the set screws and have it work in a horizontal fashion. With some adjustment you can make the head perfectly parallel allowing you to tap horizontally which can be a difficult operation in anyone’s book to do. Using this function you get a really accurate tap with depth and torque speed control ensuring good accurate work. Then it’s a very simple operation to bring it back to parallel. I simply use a one-two-three block on my table to set and make sure that the head is perpendicular with the table in both directions before I snug up the set screws to get the position tight and set. Once I get it parallel in both X and Y direction it’s set and square again.

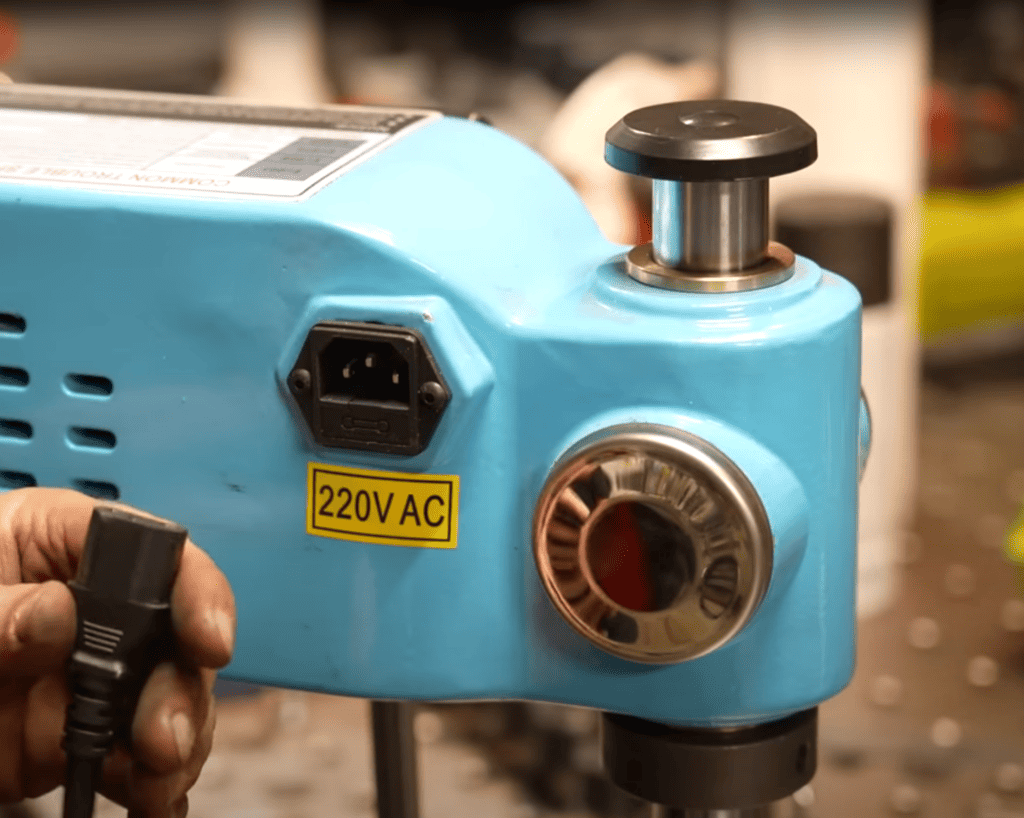

Power Required

You need to be aware that this tool runs on 220 volt which is perfect for Australia but you will need that voltage capacity where you are. I understand that 220 volt is an option for the States but I’m not sure about Europe. The device requires a very standard three prong power cord “jug lead” commonly used to power computers and computer equipment. You will have to source a power cord that is suitable for your country’s requirements. I bought a heavy duty cord as I use it in a metal shop and you can simply put your local plug on it, the one I got came from Amazon.

Flexible Arm Movement

The articulated arm of the tapping machine allows you to move the head to any position on your work table. The tapping head will stay perfectly parallel or horizontal with the work table no matter where you have work. This makes drilling and then tapping a series of holes within an engine frame a breeze to perform. When you know that every hole and tap is going to be exactly the same coupled with the support of the arm controller you won’t dread the tapping process again.

The whole arm basically rotates on the main column and there’s a collar underneath the arm where it’s simply a matter of loosening the set screw inside the collar and very quickly you can get the arm to raise or lower. Generally I keep it kind of in the middle setting but it doesn’t really matter as long as you can get down to the part that you’re trying to tap. The arm will actually drop below the support base so you don’t really need to worry too much about what the height is, more likely you will be avoiding something on your workbench or having to work around the setup that you have. The Arm is not super heavy and when you need to remove it off the column you just unscrew the cap on top of the column and you can lift the whole thing off.

Tapping Machine with supplied Collets

The Tapping Arm uses GT12 Collets to hold drills and taps and I should describe how they work and what you’ll need to use the Arm with standard imperial taps. The Tapping Arm comes with a set of torsion GT12 chuck holders ‘Collets’ that are not very useful as I found that not many taps fitted these holders. These Collets are interesting as you can adjust the torque setting of the holder as there’s a series of clutch balls that stop the rotation depending on the torque, similar to an electric drill.

As the Collets that came with the set did not work for me I would suggest that you also purchase a set of GT12 ANSI standard inch or fraction tap holders and likely a set of CT12 Collets for Metric taps as well to keep you out of trouble.

ISO-GT12 Holder Options

The ISO-GT12 holders appear to be fairly common and you may find some useful options if you undertake a search for tools of this format. A useful addition that I also purchased included a ‘socket’ style driver similar to the end of a socket wrench. Not only will this allow you to use the tool on the end of a socket wrench which makes a useful addition for tightening any bolts but you can also use it with a universal tap holder which will be very useful when tap shank sizes vary.

Also consider purchasing a drill chuck in the ISO-GT12 shank which will fit into the tool holder as well, these usually don’t come with a clutch but the Arm can be set to automatically retract if the torque on the motor happens to get too high.

Securing an Articulated Tapping Arm

A Tapping Arm will need a pretty sturdy work surface for it to be bolted down to and you’re going to want a vise or a way for the work piece securely. To hold your work a quick acting drill vise that you commonly see being used on a drill press can be used. One of the things you’re going to want to be aware of is you will need to clamp the Vise in some way because the amount of torque that the arm can put out is honestly shocking. So if you don’t have this Vise clamped, you will spin it when you go to tap a piece of material.

Typically you could have this attached to a bench and hole parts in a secured standard vise, alternatively you could mount it to a welding fixture style table if you are working on frames or big setups. The Tapping Arm can be moved around and clamped down allowing you to tap a part that was anywhere on the table, and that’s a huge advantage compared to using something like a Tapmatic on a bridge port or on a drill press. Where, especially on a Bridgeport, you have to go and turn the knobs and levers to very precisely position to work on the part. There is a lot of forgiveness using a tapping arm machine in where your actual tool is you can really tap things in all directions and from the sides

Who Should Purchase One?

This isn’t a product for everyone, but for me this has made me thousands of dollars because of the accuracy and the speed that I’m able to do jobs without busting and imbedding broken taps and ruining parts. Generally I have every option for tapping including rigid tapping with CNC machines, a Tapmatic and rigid tapping machines set up on a bench just for tapping holes. Using them is a breath holding experience as you just don’t know if it’s going to work. Despite having all these other ways to cut a thread, when I can, I choose to use this flexible tapping arm machine if I can.

The Tapping Arm comes in the two options of either electric versus pneumatic. The electric version has the simple benefit that you can just plug it in and move it around the shop wherever you like without having to have to sortout an air supply. You can also take it to someone else’s shop if you need to help out. The electric option also gives you finer control and fine setting controls that are just not possible with the pneumatic, I’m sure you can get the pneumatic version working with torque settings but I think there will be a lot of experimentation required and I would rather have a working accessory that’s going to make my life easier and my work quicker.

Electric Tapping Arm Machine – Suppliers

I simply purchased mine from Amazon and it cost me a bit above two thousand dollars Australian by the time I was done with duty fees and a number of optional collets holders that I bought. The good thing when you are buying from Amazon is you are going to get a level of customer service that you might get from a seller on the web. Buying the Arm from Amazon also gives you a good sense of security if you do have any problems. If the product arrives faulty or damaged or fails after some use you can just ship it back and get your money back. If you’re looking for a tapping option I would forget about buying other tapping tools such as a Tapmatic and I would save my money and I would buy one of these. This Articulated Tapping Arm is super accurate and makes workflow super fast and for me in my shop and it’s nothing but a pleasure to use.