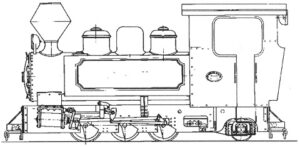

I’m thinking about making a model engineering kit for the Bundaberg Fowler ‘Bunyip’ steam locomotive that I am currently building. There don’t seem to be many options out there for a new builder or experienced alike. Putting together the following ideas is a way for me to work through the possibility and consider the pros and cons.

The standard process for building a steam engine is that you find a locomotive that you like and hopefully there is a supplier who can provide some iron castings of the hard to make parts and a set of plans. When you’re lucky there might be a build series in a magazine for your engine or similar that you can follow for the building process. So the builder is setting themselves a significant task and this is the reason why some locomotives languish unfinished. Setting out on this journey I am asking myself what would make the building process simpler and more successful?

Considering Making a Large Scale Model Engineering Kit

So perhaps I’m asking myself what moves the ‘needle on the dial’ from being difficult, challenging and long to being a more enjoyable achievable project? From where I am now building a large scale model steam engine, I feel that a set of castings, a sheet of plans and build instructions from a magazine still makes the process a daunting task.

Current Live Steam Locomotive Kits

What is available currently for large scale live steam locomotive kits? Looking at a number of local and overseas suppliers the standard offering appears to be casting and sets of plans. A number of suppliers are starting to offer laser cut parts for frames and other sheet metal components.

Generally I see that for the larger scale locomotives very few suppliers offer machined parts that a builder may need during construction. Occasionally you hear of enthusiasts getting parts commissioned by others to manufacture such as engine rod sets, cylinders and large parts that are hard to make in a standard sized home workshop. .

Making a Kit – What Do We Include?

So there is a current standard for what a builder should expect to receive in a kit. We can work to customise what a kit might look like and see if it is practical for both the builder and the person making the kit. So after a bit of thought I have come up with the following concepts. Please note that these are concepts only and I don’t offer these at the moment.

| Casting Kit | Castings and a plan set |

| Intermediate Builders Kit | Castings and plan set Laser Cut parts |

| Advanced Kit | Castings and plan set Laser Cut Parts Raw stock for other components |

| Complete Kit | Castings and plan set Laser Cut Parts Raw stock for other components Steam Fittings, Valves, Fasteners |

| Machined Complete Kit | Machined Castings and plan set Laser Cut Parts Raw Stock for other components Steam Fittings, Valves and Fasteners |

Model Engineering Kits – What do we include?

Casting Kits are the staple form of offering for the Large Scale Builder. Given time and patience model engineers have been producing fantastic working models often from the simple home machine shop, using basic casting kits to start.

Intermediate Builder Kit which includes accurately cut laser cut parts would appear magical to an old time builder, particularly if the maker asked the laser cutter to mark out the position of bolt holes and other features to make the build process even faster. I truly think that given the accuracy improvements and time saving that laser cut parts represent they should be offered as an option for any kit.

Advance Kits which include all the raw materials and stock required to build a locomotive all in one go could represent a significant time and hassle saving for any builder. With smaller model kits such as Sturt Steam engines it is not uncommon for the required materials to be included.

A supplier is more likely to get a better price on the raw stock as they are going to be purchasing it in bulk. I think that the main reason this is not commonly done is because of the cost of transportation preventing it from being adopted more widely.

Complete Fitting Kits could save a builder some significant time finding appropriate parts and components. Fittings such as valves and gauges are only needed at the end of a build. Nuts, bolts and rivets are required throughout the build and could be supplied but I think it would be easier for the builder to source these locally. Perhaps including them would be more convenient but could simply be replaced with a needed parts list.

Machined Component Kits do get me excited and I think they are most likely to move the needle towards ease of construction. They are the hardest idea for a supplier to achieve and having completed machined parts in stock might be a stretch. Making them to order might be a good medium that could be considered.

Kits for Different Build Stages

This would consist of a live steam locomotive kit that is available as a series of smaller kits based on the standard stages that a builder would progress through at different times of the engine build. This idea is a bit of a winner, for both the builder and the kit maker, as it would allow for supply time and also be more economical for the builder.

Separate kits for different build stages could allow the parts to be provided when needed such as a Frame kit, Wheel and Suspension kit, Rod & Crank kit and a Cylinder kit. As you can see from this cylinder kit below all the necessary parts for a successful build are included. All the castings are included, piston rings, end plates and raw stock all in a single bundle.

As an option for the Stage Kits some machined parts might be able to be offered as an option where the machining of that particular part is difficult due to size, machining large cylinders comes to mind.

Do Build Stage Kits Win?

Overall I do think that they do. Build kits based on stages might provide a builder with a great option for undertaking and building a live steam locomotive. I am going to start considering how I might start putting these kits together and what might be included. Providing options to be builder to help with the building process is something that I am going to look at and letting each builder decide what would help them will be the direction – moving forward.